Beer is a beloved beverage enjoyed by millions worldwide, and within the world of beer, lager holds a special place. Lager is a type of beer known for its crisp and refreshing taste, making it a favorite among many. But have you ever wondered how this delightful brew is made? In this comprehensive guide, we will take you on a journey through the art and science of lager beer production, from the selection of ingredients to the fermentation process and packaging.

The Foundation: Malt, Hops, Water, and Yeast

At the heart of every lager beer is a harmonious blend of four essential ingredients: malt, hops, water, and yeast. Each component plays a crucial role in determining the beer’s flavor, aroma, and overall character.

Malt: Malt provides the fermentable sugars necessary for yeast to produce alcohol and carbonation. It also contributes to the beer’s color, body, and sweetness. In lager production, malt is typically made from barley, although other grains like wheat or corn can be used to create unique variations.

Hops: Hops are responsible for imparting bitterness, aroma, and flavor to the beer. Different hop varieties offer a wide range of characteristics, from citrus and floral notes to earthy and spicy tones. The choice of hops influences the beer’s style, such as a light pilsner or a robust bock.

Water: Water, while often overlooked, is a critical ingredient. The mineral content, pH, and purity of the water affect the beer’s overall taste and mouthfeel. Regional water profiles have a significant influence on beer styles, such as the soft water of Pilsen, Czech Republic, for pilsners.

Yeast: Yeast is the microorganism responsible for fermentation. Lager beers are typically fermented with Saccharomyces pastorianus yeast strains, known for their ability to ferment at lower temperatures. Yeast converts the sugars from the malt into alcohol and carbon dioxide, creating both the alcohol content and carbonation in the beer.

Mashing and Boiling: Transforming Ingredients into Wort

The beer-making process begins with the mashing of malt. The malt is mixed with hot water in a process known as mashing, where enzymes break down the starches in the malt into sugars. This sugar-rich liquid, known as wort, is the foundation for the beer.

After mashing, the wort is separated from the solid grain material through a process called lautering. The wort is then boiled, and hops are added at various stages during the boil. Hops contribute bitterness early in the boil, flavor in the middle, and aroma late in the boil. The boiling process sterilizes the wort and extracts the flavors and aromas from the hops.

Fermentation: Transforming Wort into Beer

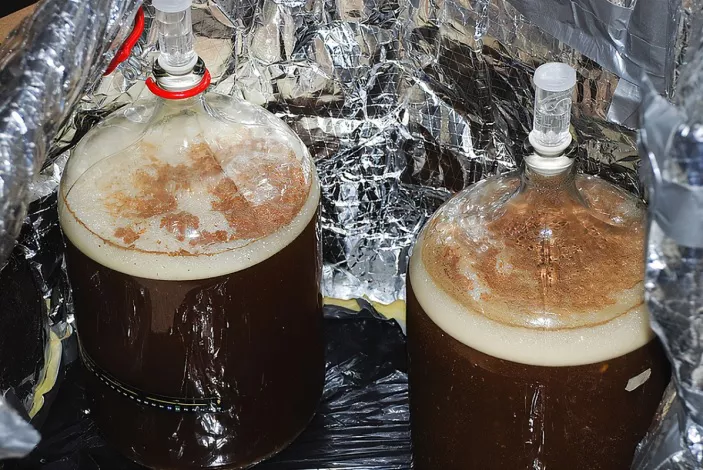

Fermentation is the magical step in beer production where yeast consumes the sugars in the wort, producing alcohol, carbon dioxide, and a wide range of flavors and aromas. In lager production, this fermentation process occurs at cooler temperatures than in ales, typically between 45°F and 55°F (7°C to 13°C). This cooler fermentation results in a cleaner, crisper taste, which is characteristic of lagers.

After fermentation, the beer may undergo a maturation or conditioning period. This stage, known as lagering, involves storing the beer at near-freezing temperatures for several weeks to several months. This extended cold storage allows any remaining yeast and undesirable compounds to settle and results in a smooth and clean final product.

Styles and Variations

Lagers come in a wide variety of styles, each with its unique characteristics and flavor profiles. Some popular lager styles include:

Pilsner: Named after the city of Pilsen in the Czech Republic, this is the world’s most popular lager style. It is known for its pale color, crisp and refreshing taste, and prominent hop bitterness.

Bock: Bocks are stronger lagers with a richer, malt-forward flavor. They often have notes of caramel and toffee and can range from amber to dark brown.

Dortmunder Export: Originating in Dortmund, Germany, this lager style falls between a pilsner and a helles in terms of flavor and color. It’s well-balanced and easy-drinking.

Vienna Lager: This amber lager style, originally from Vienna, Austria, has a toasty, caramel malt character with a mild hop bitterness.

Märzen: Märzen lagers are traditionally brewed in March (hence the name) and then lagered until the fall. They have a clean, malty sweetness and are often associated with Oktoberfest celebrations.

Helles: A German style that translates to “bright” or “pale,” helles lagers are light and malt-forward with a mild hop presence.

Packaging and Enjoyment

Once the lager has completed fermentation and any required maturation, it is ready for packaging. Lager beer is often packaged in bottles, cans, or kegs. It’s essential to store lager beer in a cool, dark place to preserve its freshness and prevent flavor degradation.

Conclusion:

Lager beer is a versatile and widely appreciated style that embodies the artistry of beer production. From the selection of ingredients to the mashing, boiling, and fermentation processes, every step is guided by tradition and expertise.